Someone asked a while back, "What is a swedge and what are they used for?" Tony and I sat at the kitchen table with this stockman and talked it over. I learned that swedges have 4 basic purposes:

1. They improve the eye appeal of a blade.

2. They make the blade thinner at the spine and therefore improve it's ability to cut.Specific to slip joint folding knives they:

3. Make room for the blades to pass each other when opening and closing.

4. Provide access to nail pullsThis 3 blade premium stockman has some good examples of swedge work. From the top you can see that there isn't a lot of extra room for blades. The swedges on each blade play a part in making this knife work well. Imagine what this knife would look like without swedges. Eye appeal is definitely at work here in the lines on these blades.

There wasn't much worry about blades rubbing on the old knives because they were USED! In today's collector market, blade rubs are a no-no so care is taken to make sure there is plenty of room for the blades to pass. But, you don't want a knife that is too wide so swedges will enable the maker to keep the knife as narrow as possible.

Now take a look at the position of the blades in the image below.

The master clip blade has symmetrical cut swedges. It has it's own spring and therefore it's own pocket to house in, but still the sheep's foot blade is very close. The drawn swedge of the sheep's foot and the cut swedge of the clip blade allow plenty of clearance.

The spey and sheep's foot blades share a spring. Special attention has to be paid to make these two blades play nicely together. A cut center liner(not a full profile liner) is used and the sheep's foot blade is crinked(bent) toward the center. You can see in the image above that the tip of the sheep's foot blade is about centered over the center liner. Crinking one blade doesn't provide enough clearance between blades so cut swedges are employed between the spey and sheep's foot blade.

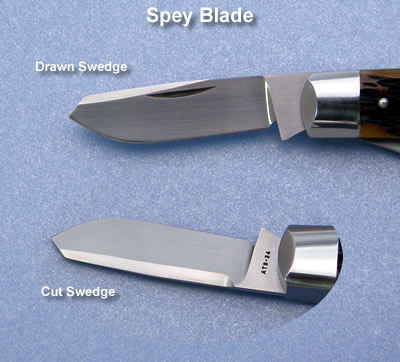

There are

2 types of swedges: cut swedge and drawn swedgeThe cut swedge plunges in where it begins on the spine and tapers out towards the tip. A correct swedge will end before it gets to the tip of the blade. Otherwise, blade sharpening over time could potentially involve the swedge resulting in an ugly blade.

The drawn swedge tapers gradually from where it begins on the spine and tapers out again toward the tip.